The DTT GDC System: the preliminary design

The “quality” of the wall surface plays a crucial role in the attainment of a robust start-up and good plasma performances in fusion devices.

In the DTT two tools are synergically used to prepare the tokamak full-tungsten wall (divertor, first wall, and vacuum vessel) for the experiments: the backing and the Glow Discharge Cleaning & Conditioning (GDC) systems.

Backing (wall treatment up to 170 °C) is used to release by evaporation gasses weekly trapped in the surfaces. GDC allows removing deeply trapped impurities by high energetic ions imping onto the surface.

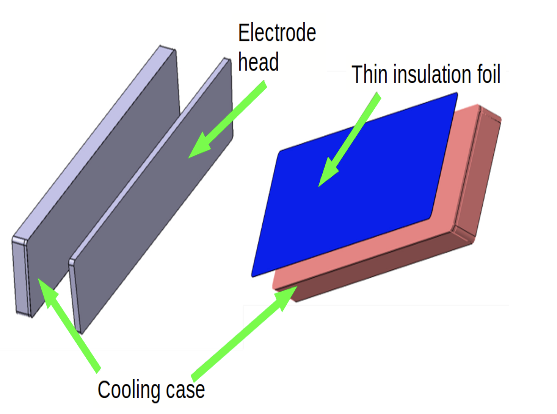

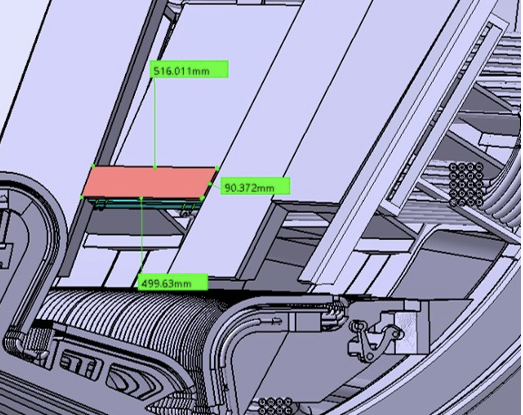

The preliminary design of DTT GDC system has been successfully carried out. A set of 6 anodes is distributed all along the torus, electrically insulated from the cooling case and kept at ground potential using an insulation foil (fig. 1 and 2); the anodes are fed by a voltage of the order of some hundreds of Volts and a total current of 24-30 A. The system is actively cooled to withstand up to 0.5 MW/m2 radiated plasma power.