Progresses on the design of DTT water cooling system

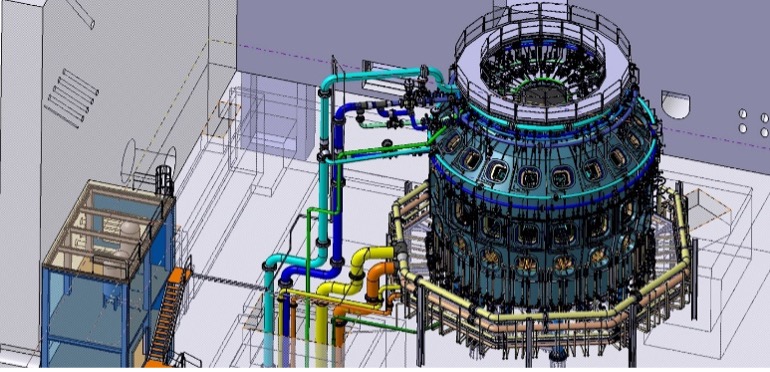

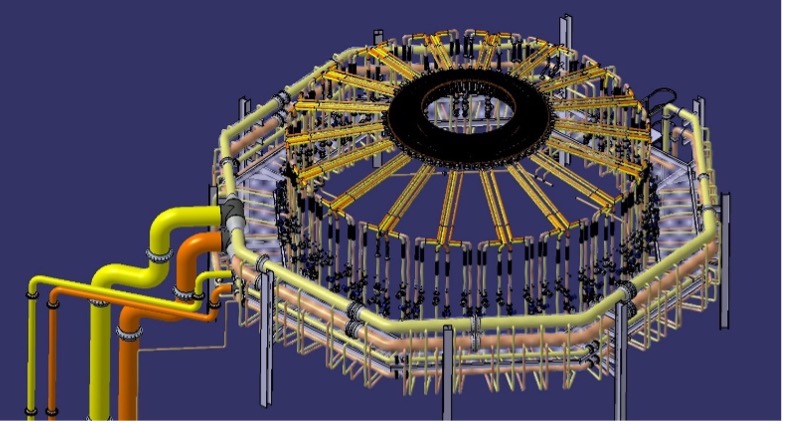

The DTT Water-Cooling System (WCS) is designed to ensure the temperature control in the main plasma-facing components, such as First wall, Divertor and Vacuum Vessel.

The WCS is a very critical system: (i) for the challenging performances required (for example, it is designed to remove up to 32MW from the FW during the 100s-pulse); (ii) for the impact on the machine layout (for example, it must allow the Remote Handling System to cut and welding all the pipes inside the cryostat); (iii) for the complexity (for example, more then 400 -manual or actuated- valves are included to identify and manage possible leakages and, in addition, the disassembly of the port plug is allowed without removing the pipes jungle; (iv) for the sophisticate control capability (for example, 84 ultrasonic mass flow meters continuously monitor and control the water flow, allowing a full maintenance without disassembly the pipes)

A contract, for approximately 25 PM, was recently launched for the definition of the specifications, drawings and thermomechanical analysis required for the construction tender, scheduled for spring next year. Participating in the contract are Ansaldo Nucleare (in the framework of the general collaboration contract signed last year) and, as a subcontractor, Promech.

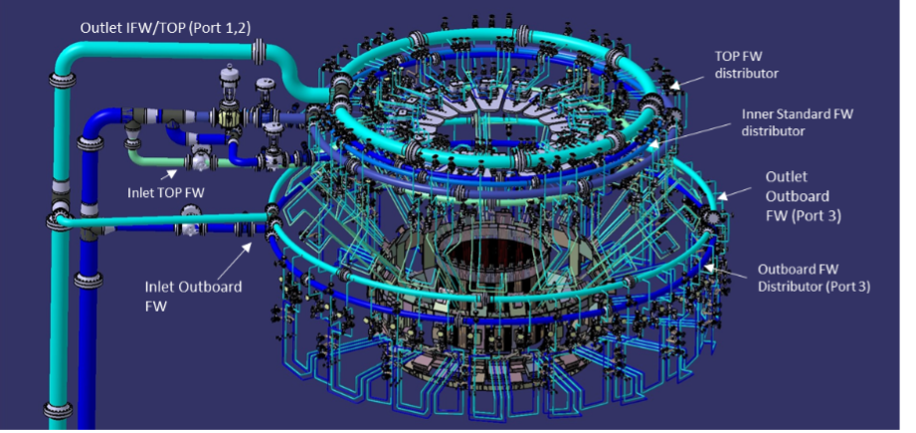

Lay out of First Wall WCS