Preliminary successful results of DTT divertor mockups

A severe experimental test program on two small-scale mockups of DTT Divertor, is underway at the Garching LArge DIvertor Sample test facility, GLADIS (IPP-Garching, D); the test protocol reproduces the coolant and heat loads cycles close to the conditions expected in DTT. The preliminary results are very satisfying.

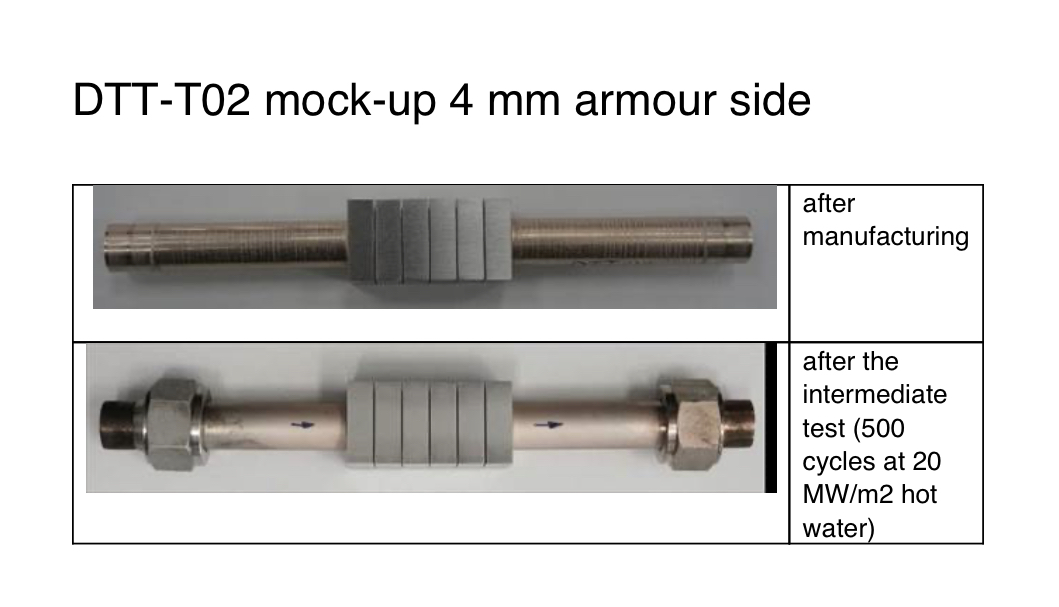

The DTT divertor design is based on the monoblock concept, i.e. an heat exchanger where copper-chromium-zirconium actively cooled tubes are protected by tungsten massive tiles. The mockups have been manufactured at ENEA Frascati following the Hot Radial Pressing process, an ENEA patented procedure, successfully used for the fabrication of ITER target prototypes.

The heat flux expected on DTT divertor target (up to 20 MW/m2) is very challenging; therefore, the assessment of the thermal fatigue performance is a key point of the DTT design.

Intermediate test results have demonstrated the capability of the geometry and the manufacturing technology of the plasma facing component to sustain without damage the thermal stress expected during the DTT operating life.

The test campaign is in progress with the aim to complete the full 1000-cycles, 20 MW/m2, test program.