New advances in DTT Vacuum Vessel Design

In view of the preparation of the tender for its construction, important updates have been introduced to the DTT Vacuum Vessel project and to the definition of its specifications.

The philosophy that animated the revision is the simplifications in the manufacturing process and in the procurement of special components like port bellows and machine instrumentation with the aim to reduce the construction and maintenance costs.

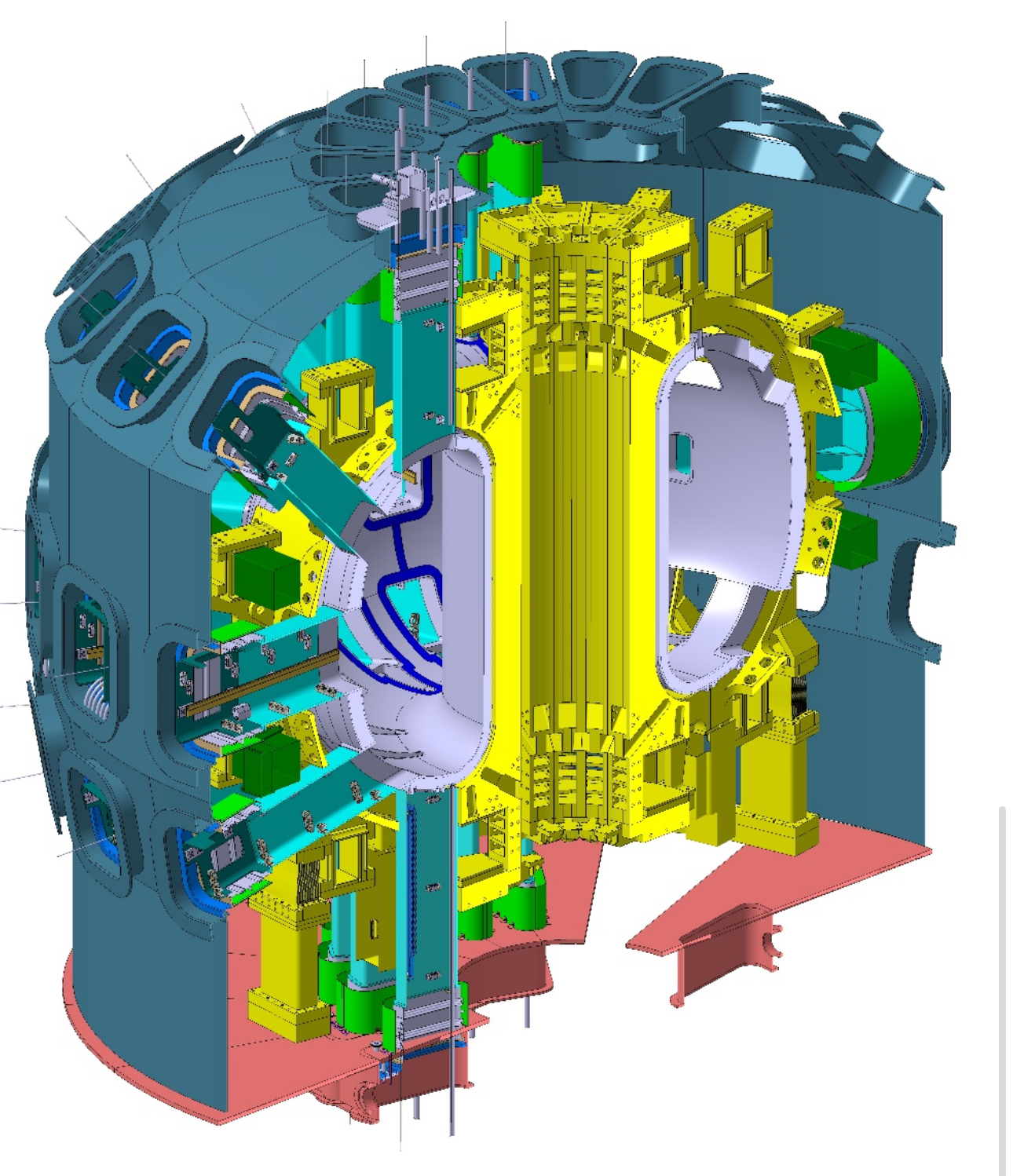

In particular, the port design has been improved by enlarging thebellows and elongating the ducts towards the cryostat flanges thus reducing the distance between the installation rack and the vessel port (Fig. 1). Such measures are able tofacilitate the assembly of the in-vessel components through the ports, thereby minimizing the number of required assembly operations then reducing costs.

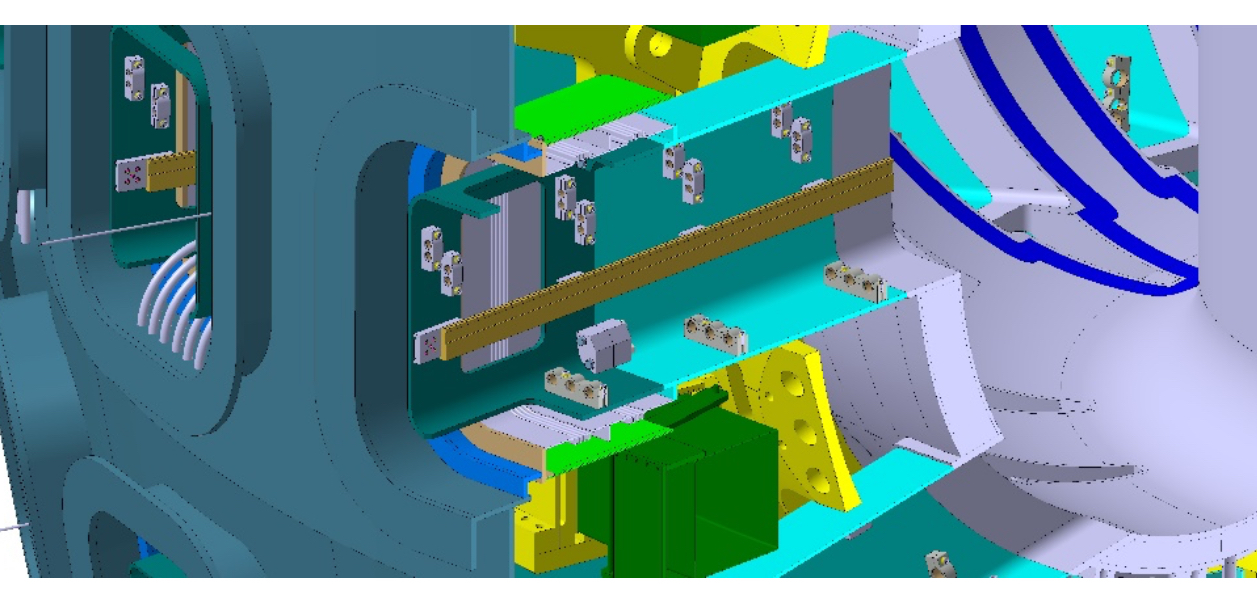

Bellows at “standard sectors” have been unified: the same design has been applied for the bellows with triangular section positioned at the top and bottom ports (port locations #1 and #5) and for the bellows with rectangular section positioned at the lower middle and upper middle ports (port locations #2 and #4).

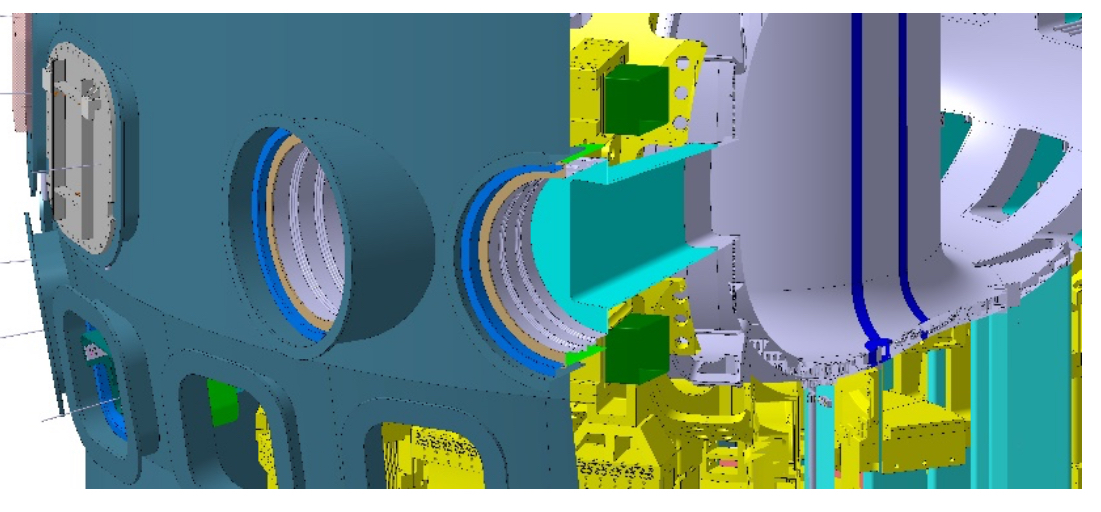

The total amount of 82 port bellows includes those located at the tokamak equator and designed with rectangular section at “standard sectors” (Fig. 2) and with circular section at the “special sectors” (see Fig. 3 with toroidal locations #7 and #8).

Fig.3