DTT Hyper Redundant Manipulator: design and construction activities started

As part of the proposal for "Rafforzamento e creazione di Infrastrutture di Ricerca" (“Strengthening and creation of Research Infrastructures “) financed in 2022 to ENEA by the Italian National Resilience Recovery Plan (PNRR), the DTTU (Divertor Divertor Tokamak Test facility Upgrade) project has been launched. The project consists in upgrades of the DTT facility under construction at ENEA Frascati Research Centre.

One of the DTTU workpackages is the design and construction of REMote HAndling Test facility (REMHAT) that will be installed at Centro Servizi Metrologici e tecnologici Avanzati (CeSMA) – University of Naples Federico II, Italy, just a couple of hours by car from DTT premises. The facility will consist of a mock-up of 120 degrees of the DTT tokamak equipped with the systems and end effectors foreseen to handle the DTT Divertor Cassettes and the First Wall components. The REMHAT facility will employ the same equipment that will be used for DTT RH operation or functionally equivalent mock-ups, that will be created as part of the development activities. It will be used for final development of RH systems starting from prototypes and will allow to qualify the remote handling operations of the plasma First Wall components, FW modules and Divertor Cassettes.

Hyper-Redundant Manipulators (HYRMAN) and the Cassette Multifunctional Mover (CMM) will be manufactured and installed in the REMHAT at CeSMA to qualify the system and the procedure developed.

Here some specific information about HYRMAN is provided.

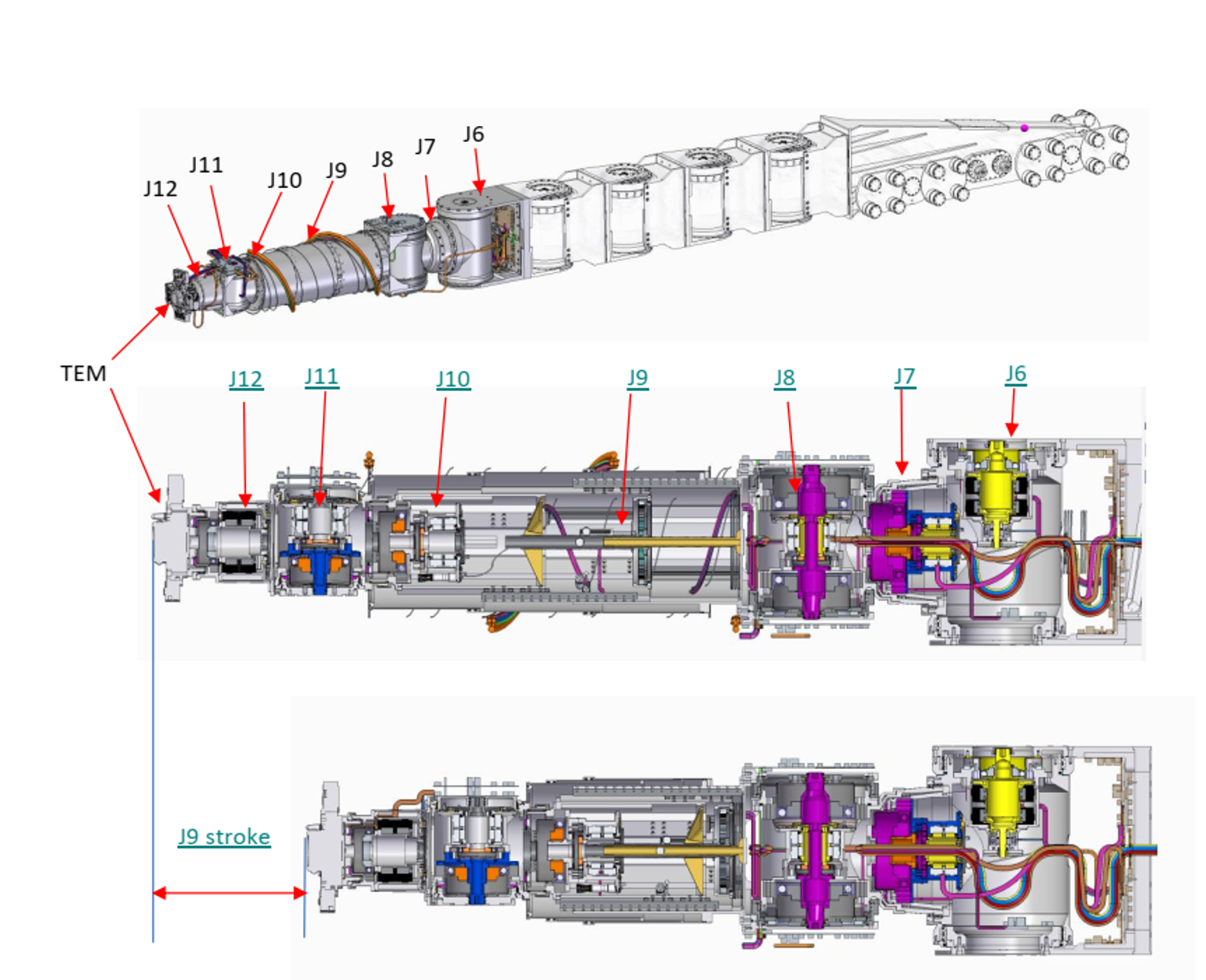

HYRMAN systems (Fig. 1) are devoted to the maintenance of the DTT first wall components and will be operated through the equatorial port. However, the first destination of the two Hyrman systems will be the DTT REMHAT facility.

Two HYRMANs have been ordered and will be supplied by the company OCIMA (Figg. 2-3). OCIMA, with more than 30 years of international experience in designing and building machines for industrial processes automation, will be responsible for the final engineering design and manufacturing of both the Hyrman systems.

The Kickoff Meeting between OCIMA and ENEA-DTT has been held recently. The meeting gave the opportunity to discuss the technical content and the timing for the realization. Design and manufacturing activities are now proceeding with the supervision from the ENEA-DTT team.

Figure 3 OCIMA premises : the workshop