In view of the announcement of the tender of the Assembly of the DTT Tokamak system, the DTT Team is making a huge effort to define the specifications of the procedure.

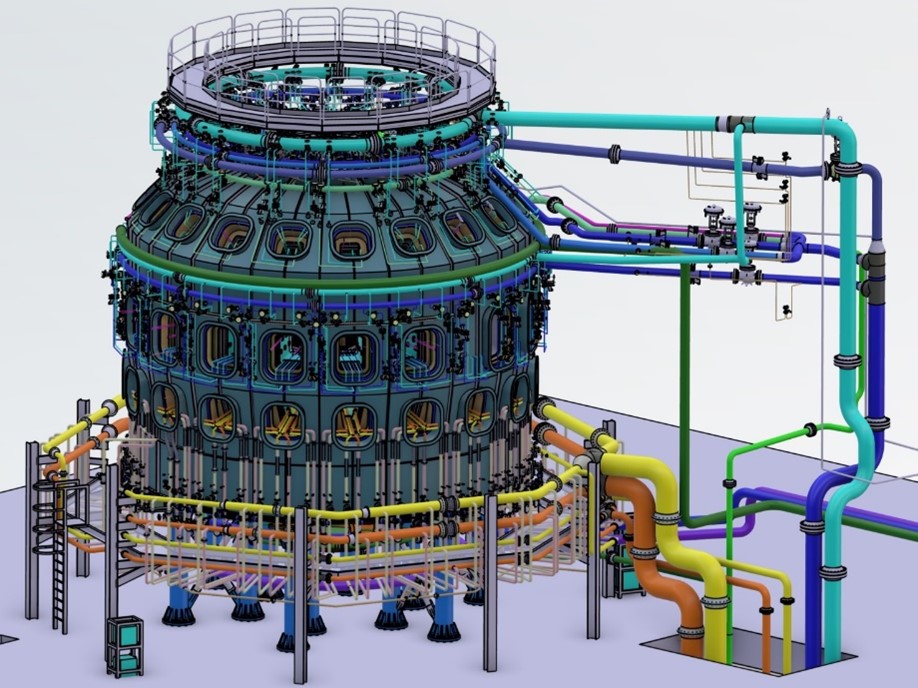

In fact, the assembly is one of the most critical steps in the realization of the DTT facility (see Fig. 1 for a general rendering view of the machine).

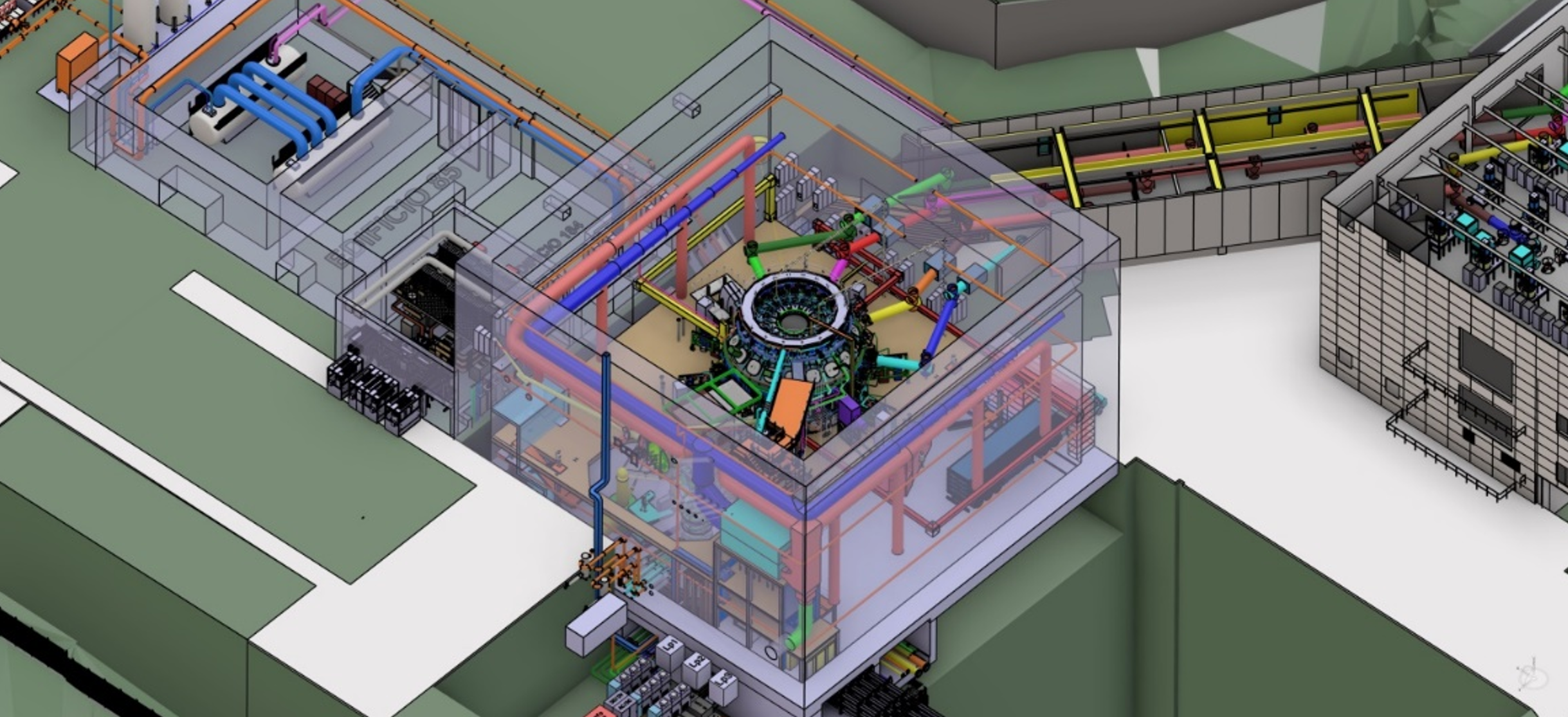

The assembly of the machine will be carried out from the bottom to the top; il will begin with the cryostat base (60 t), continuing with the two large vacuum vessel sectors (extension 170 toroidal degrees, equipped with the thermal shield panels, weight 21 t, each), the toroidal (27 t each) and poloidal field coils (17 ÷30 t, each) and, then, the central solenoid (50 t). In Fig. 2 the machine assembly is sketched while in Fig. 3 the rendering view of the Tokamak building is reported.

In order to meet the ambitious physical performance assigned to the DTT program, the tolerance in the assembly of these so large and heavy components must be carried out within a very tight mechanical tolerance (i.e., < 2 mm in the TFC pair alignment). For this reason, the assembly process is one of the biggest challenges of the DTT program.

The tender announcement for the DTT assembly is scheduled for the end of this year.

Fig. 3 – Overview of Tokamak building with ancillary plants